Sheet Metal Contractors

Sheet Metal Experts in Melbourne

For top quality sheet metal fabrication, look no further. We are Metfab, we are experts in all things steel.

Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. The completion of a product usually comprises of many steps – from cutting and bending to surface treatment and assembling.

Often times a variety of fabrication techniques can be used to achieve a similar end-result. But a right choice still exists, depending on the costs and needs.

Types of Sheet Metal Fabrication

Mechanical Cutting

Shearing, or die cutting, refers to a process that cuts sheet metal without burning or melting it. Also, it does not produce any chips. In essence, shearing is not too different from cutting with scissors.

Punching

Punching is another way for cutting holes into a sheet. A metal punch hits the sheet, perforating it. It is suitable for large-scale production but not cost-effective for smaller jobs. The reason lies with the need for a separate tool for different cuts.

Assembly

Assembling is the ultimate or penultimate step when you want to fabricate a product. If assembling includes welding, the parts have to be clean – you can then have it powder coated, or whatever you need.

Sheet Metal Logistics

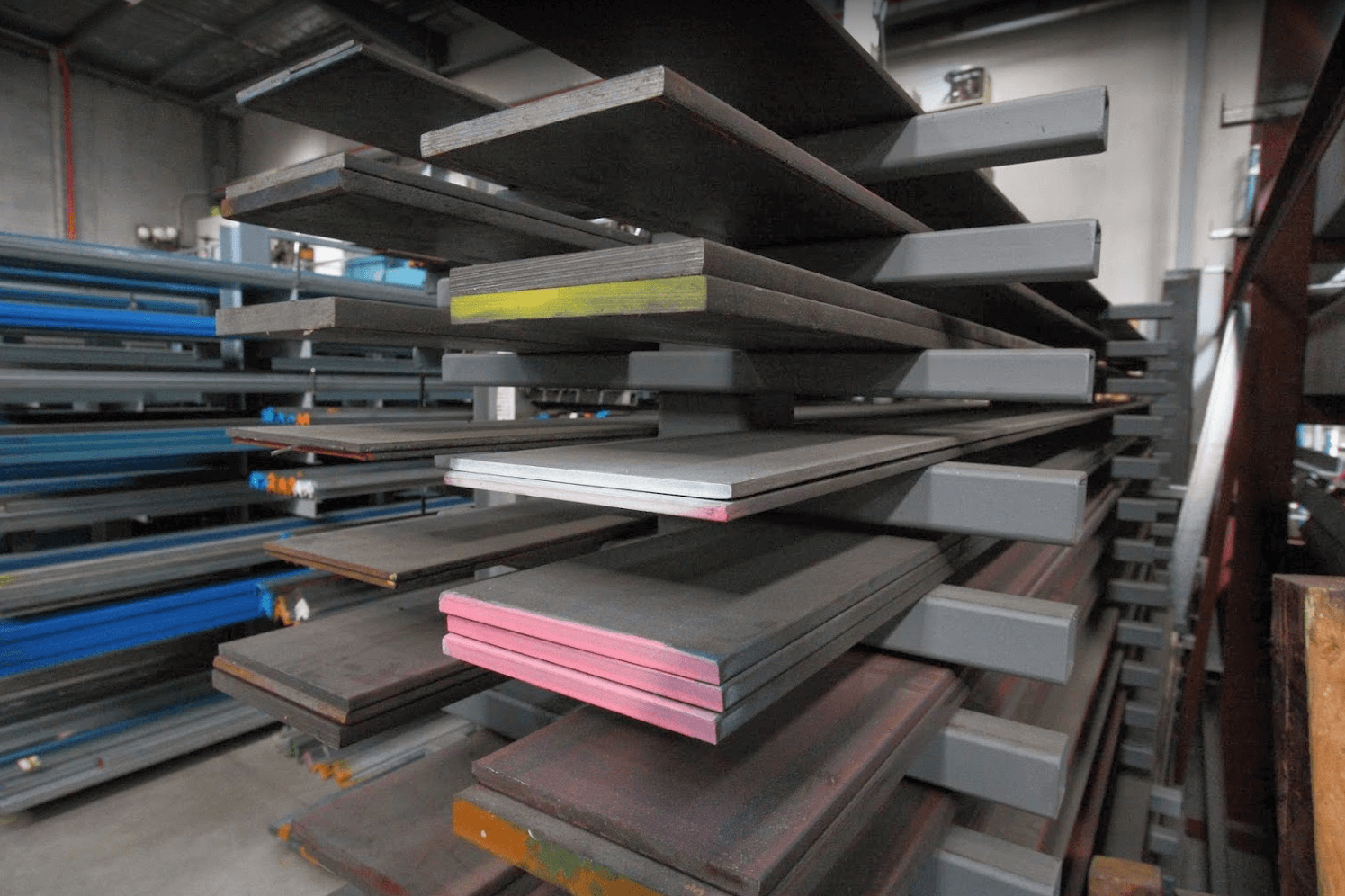

The Metfab factory is a large workshop that houses a talented team of sheet metal fabrication experts, qualified tradesman, with years upon years of experience. We create the masterpiece, but we also get it delivered to your door.

Our large warehouse facility houses all our steel products, along with your everyday fittings and steel needs that might be a last-minute requirement. We always keep stock on hand for your emergencies.

Daily deliveries are a part of our service at Metfab, we also have to flexibility to deliver all over Melbourne.

Our goal is to keep your business moving fast, as well as ours.