Basic Sheet Metal Fabrication Techniques

What Are Fabrication Techniques?

Solid freeform fabrication techniques (SFFT)

SFFT, such as fused deposition modelling, have been employed to fabricate highly reproducible scaffolds with fully interconnected porous networks. SFFT refers to computer-aided manufactured (CAD/CAM) methodologies such as stereolithography, selective laser sintering, ballistic particle manufacturing and 3D printing. SFFT offers the possibility to fabricate polymer scaffolds with well-defined architecture because local composition, macrostructure and microstructure can be specified and controlled at high resolution in the interior of the components. This technique has been applied for composites containing calcium phosphates as the bioactive phase. For example, Xiong et al (2002) fabricated PLLA/TCP composites with porosities of up to 90% and mechanical properties close to human cortical bone by using low-temperature deposition based on a layer-by-layer manufacturing method. Taboas et al. (2003) produced PLA scaffolds with computationally designed pores (500-800 μm wide channels) and solvent-derived local pores (50-100 μm). However, a shortcoming of this route is increased scaffold fabrication time and complex equipment requirement compared with direct methods.

How Do You Perform Sheet Metal Fabrication?

When people are taught how metal fabrication works, the following processes are usually part of the training program. Each process takes a degree of practice and skill to master, and the tools and machines required are usually expensive and consume sufficient working space. However, each metal fabrication process may be used to cut, drill, fold and weld the strongest material on earth:

- Cutting. Perhaps the most commonly used metal fabrication processes involve cutting, where sheets of metal are split into halves, thirds or smaller sections. In a lot of applications, the metal being cut is freshly made and has yet to be shaped into anything in particular. In other applications, pre-shaped metals like bars and measured panels are submitted for cutting. Cuts are performed on a range of machinery, from lasers and plasma torches to more elaborate, high-tech pieces of machinery.

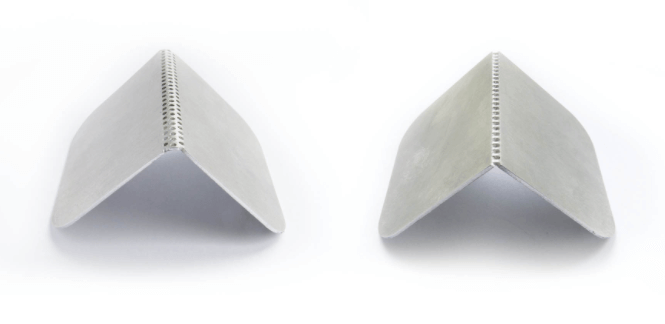

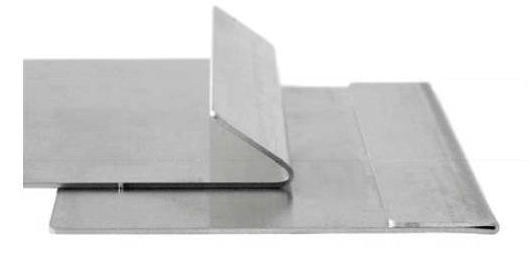

- Folding. One of the more complicated processes of metal fabrication involves folding, where a metal surface is manipulated to shape at a certain angle. With certain folding applications, the intent is to make the metal surface fold at a 90-degree angle, or something else that’s either more or less blunt. However, folding may only be performed in facilities that are equipped with specific, high-tech equipment due to the complexity of the whole process. In many cases where a fold is needed, the joining of two metal panels at select angles would be the more practical alternative.

- Welding. Along with cutting, welding is one of the most popular metal fabrication processes among crafts enthusiasts. The process of welding involves the joining of two separate metal parts. The parts used in a welding application could be sheets, panels, bars or shapes — as long as the parts are made of metal, it really doesn’t matter. Welding is achievable through numerous methods and tool types. Often, a weld is achieved through the application of heat along the points where the two pieces are meant to be joined. A lot of metalworkers first pursue the area of metal fabrication with welding projects in mind.

- Machining. When a machine is used to remove portions from a piece of metal, the process is known as machining. Typically, the process is performed on a lathe, which will rotate the metal against tools that trim corners and edges to cut the piece down to a desired shape or measurement. In other machining applications, a hole or set of holes will be formed directly through the metal surface. As such, the metal drill could be classified as a machining tool.

- Punching. When holes are formed in a piece of metal, the process involved consists of punching, where metal is placed under a die and submitted to a punch-through by a drill. For the punch to be the correct size, the circumference of the drill must slot correctly through the die. Punching falls into one of two subcategories based on the intention of a given application. In most cases, the intent is to punch holes into a panel of metal for the purpose of fastening latches or other foreign parts. In other applications — alternatively known as blanking — the area with the hole is specifically extracted from the larger panel to form a smaller bit part.

- Shearing. For sheets of metal that require long cuts, the process is known as shearing. In some cases, the sheet is fed horizontally through a metal-cutting machine. In other applications, a cutting tool is applied vertically against the length of a flat metal sheet. A third method involves placing the metal over the edge of an open cutter and lowering the blade, much like the paper cutters found at copy facilities. Shearing is often applied to trim down the edge of a metal sheet, but the process may be done anywhere along the metal.

- Stamping. Punching is not the only metal fabrication process to utilize a die. In some applications, however, the intention is not to form a hole, but to raise a certain portion of a metal sheet, without penetrating. For applications like these, the process of stamping is used to form certain shapes, letters or images within a metal sheet or panel. In effect, metal stamping is similar to relief carving in wood or marble. A primary example of metal stamping is seen on coins, where words, currency amounts and the faces of presidents are stamped from each surface side on pennies, nickels, dimes and quarters.

- Casting. One of the oldest types of metal fabrication involves casting, where molten metal is poured into a mold and is left to solidify into a specific form. As one of the most flexible methods of metal fabrication, casting is ideal for a wide range of complex shape-making. In some cases, casting provides a solution to fabrication problems that would otherwise take several other methods to solve, such as with assembly parts that would need folding, shearing, and stamping. The most common metals employed in this application include steel, iron, gold, copper, silver, and magnesium.

Additional metal fabrication processes include broaching, honing, grinding and milling. Depending on the needs of a particular application, some metal facilities even perform specially customized types of fabrication

What Tools Are Needed For Metal Fabrication?

We mentioned in another blog post that there’s an ongoing great debate about whether or not apprentices should purchase their own tools. However, no matter which side of the fence you stand on, there are a few tools of the trade that every sheet metal fabricator should own at any level of experience. Here’s a comprehensive list of the tools everyone in this business should own:

- A 4 ½-inch or 6-inch (150mm) angle grinder. This handheld power tool is used for cutting, grinding, and polishing different types of metal, which metal fab workers do often, so make sure you purchase an angle grinder that's durable. There are great cordless models around these days, Bunnings have plenty of options.

- A set of Cleco fasteners. This nifty tool temporarily fastens multiple sheets of metal (typically aluminium) together before the pieces are permanently joined. Think of it as a stronger clothespin.

- Various angle grinder discs. This set can include grinding wheels, which can be superabrasives or conventional abrasives, depending on your projects; cut off wheels; and flap discs, which are used for finishing; and wire wheels. Be careful when purchasing grinding discs, for example, a masonry disc is for use on concrete, not steel.

- A throatless shear. This tool is made for achieving straight, curved, or irregular cuts on a metal project. It has three holes for simple mounting and features a tall handle that gives you the leverage necessary to easily cut stainless or mild steel and aluminium. Needless to say, this tool is an everyday staple in most fab workshops.

- Wire cutters. Every handyman should own a reliable pair of wire cutters for snipping frayed ends. Some call them nips here in Victoria.

- An auto-darkening helmet. These helmets can range anywhere between $200 to $400, depending on the manufacturer, but every sheet metal fabricator should invest in a dependable auto-darkening helmet for the occasional project that requires a lot of welding.

- Angle finders. Most quality angle finders are made of stainless steel or high-grade aluminium, and most sheet metal fabricators use these frequently, so splurging on a good set is often recommended.

- Cutting glasses. In this business, safety comes first. Since sheet metal fabrication projects are typically large-scale, they can pose a greater risk for accidents. A solid pair of cutting glasses will help decrease your chance of getting hurt in case of an accident. I have personally had a piece of steel stuck in my eye, you don’t want that, be safe.

You can have the Swiss Army knife of metalworking tools, but make sure you have these few basics first. The traditional, high-quality tools from the list above will help fab workers complete a project of any size throughout their career, so it’s best to splurge on these few tools of the trade.

In nature, there is no separation between design, engineering, and fabrication; the bone does it all.

— Neri Oxman

What Are The Types Of Fabrication?

Fabrication is the act of taking raw stock material and turning it into a part for use in an assembly process. There are many different types of fabrication processes. The most common are

- Cutting

- Folding

- Machining

- Punching

- Shearing

- Stamping

- Welding

- Additive Manufacturing

Fabricated Metals Used In Product Making

Forming metal pieces for assembly use is just part of the process when it comes to making metal products. The next stage involves taking different pre-made parts and turning them into machines, appliances, cookware, and other products. Depending on the operations at hand, a given set of assembly parts might go to a factory or independent craftsperson. In most cases, a project will start with one or more of the following materials:

- Expanded metal. For machines and fixtures needing metal panels that are grated instead of solid, metal is expanded to take on the desired consistency. Basically, sheets of metal are sheared in a pattern that forms diamond-shaped holes along the surface, which is held together by the remaining mesh-like metal. As the final formation of each sheet takes place, the metal is effectively expanded to its ultimate dimensions.

Expanded metal is commonly used as a protective wall on machines that need ventilation, such as along back-portion panels of computers and heaters. Panels of expanded metal are also commonplace on the fences and screen doors of condominium complexes and gated communities. The grating size on different sheets of expanded metal may vary, though wider holes are generally favoured as a fencing material, and smaller holes are often better for panels on electronics equipment. Expanded metal is also available in a variety of thicknesses.

- Sectional metals. In the construction and engineering sectors, metals are regularly ordered in sectional varieties for numerous applications. Sectional metal is any type of prefabricated piece that’s designed for standardized assembly. A construction company, for example, could need structural framing panels of particular lengths and widths, the measurements of which would be standardized throughout the industry and pre-fabricated for order from a construction-parts supplier. Common types of sectional materials include:

- I-beam. An I-shaped, cross-sectional beam.

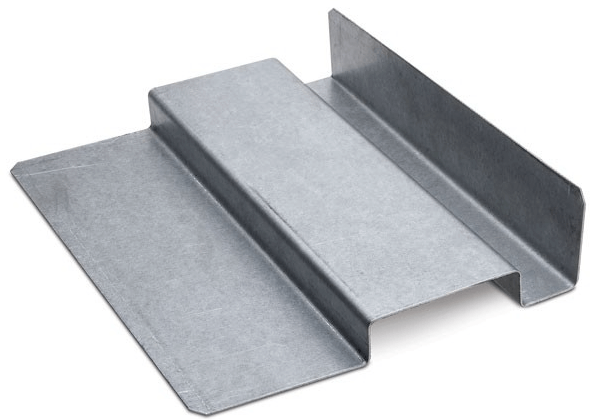

- Z-shape. A sectional piece shaped similarly to the last letter in the alphabet.

- Bar. A rectangular cross-sectional metal piece.

- Rod. A long sectional metal piece, either square or round.

The strength and contents of sectional metals are strictly defined by the American Society for Testing Materials.

- Flat metal. For any given number of applications, flat metal pieces are used in construction and industrial assemblies. Flat metal is a raw material that is fabricated in a range of thicknesses. While the pieces are generally thin, the gauge will range from under a millimetre to two or more centimetres. Flat metals typically fall into three groupings:

- Leaf metal. The thinnest kind, also known as foil metal.

- Sheet metal. The most widespread kind, which tends to be under 6mm thick.

- Plate metal. The thickest kind, which exceeds 0.25 inches.

Flat metals are commonly used to form the side panels on ovens, refrigerators and other household appliances.

- Welding wire. Used as a welding aid, the wire consists of metal strands, which are typically bound together into thicker cords and sold on spools. True to its name, the wire is used to hold two pieces of metal together during a welding application. Usually, the wire is melted into the welded piece by the heat of the application as the process takes place. Welding wire is made of various types of metal, and it is generally found in a range of thicknesses.

How Do You Cut Sheet Metal?

Many different tools cut sheet metal, and each has its own strengths and weaknesses. Here are some of the more common tools, but they represent only a small number of options.

Commonly known as aviation snips or tin snips, these scissor-like tools are great for cutting soft sheet metals such as tin, aluminium, brass, and thin-gauge (24 gauge or thinner) steel. Depending on the cut shape, you’ll use left-cut, right-cut, or straight snips, typically indicated by the handle colour: red for left, green for right, and yellow for straight. Be sure to insert the metal fully into the throat of the snips for optimal cutting.

What Are The Materials Used In Fabrication?

- From digital prototypes, M & S fabricates parts and equipment enclosures for many applications using a variety of metal alloys. Below is a list of some of the sheet metals, pipe, structural shapes, etc., that M&S regularly uses in fabrication.

- Hot rolled steel

- A36, A572-50, A606, CS-B, 100XF, HSLA Gr 50/60, HSLA-F Gr 50/60, Abrasion Resistant, Aircraft Quality

- Cold rolled steel

- 1008, 1018, 1044, 1045, 1008, 1010, 11L17, 4140, 5160, A36, M1020, A-529 Gr 50

- Stainless steel

- 303, 304, 304L, 316, 316L

- Aluminum

- 1100, 3003, 3105, 5005, 5052, 5083, 5086, 2024, 6061

- Copper

- 110, 147, C360, C10100, Type: Cold Rolled, Half Hard, Quarter Hard, Soft, Full Hard, L Hard, Type L Soft

- Brass

- 260, 330, 360, Type: H58, Half Hard, Soft

- Bronze

- C954

- Pipe

- Schedule 10, Schedule 40, Schedule 80, A500 Gr C, Gr B/C, A53 TYPE E/F Gr A/B, A53 TYPE F

- Structural Shapes

- Angle, Channel, I-Beam, Tee, A36, A-529 Gr 50, HSLA Gr 50

- Tube / tubing

- Rectangle, Round, Square, 1008/1010, A500 Gr B, HSLA Gr 70, Type: CREW, HREW, 1010, 1020, 1026, 4130, 1008/1010, 1010/1015, 1010/1020, 4140, A500 Gr B/C, J525

- Plate

- Abrasion Resistant, AR200, AR235, AR400, AR500, T-1

- Armor Plate, MIL-A-12560H C1, MIL-A-46177C, MIL-DTL-46100E,

- 1008/1010, 1010, 1020, 1030, 1045, Type: Discrete, Strip Mill, HR P&O, Laser Quality, SCS

What Is The Best Tool For Cutting Sheet Metal?

Cut Metal Fast

There’s nothing wrong with using a good, old-fashioned hacksaw, but there are faster, easier ways to cut metal. We’ll show you power tool tips and techniques for cutting the types and thicknesses of metal that DIYers handle the most.

And whether you’d like to build custom cars or just fix a cracked lawn mower deck, learning to weld gives your DIY game a serious boost. Check out this expert welder’s recommended tools and gear.

Ditch the Abrasive Grinder Discs

An angle grinder fitted with an abrasive metal-cutting disc works well to cut all kinds of metal, including bolts, angle iron, rebar and even sheet metal. But the discs wear down quickly, cut slowly and shrink in diameter as you use them. Instead, we recommend using a diamond blade that’s rated to cut ferrous metal. These will last much longer, cut faster and cleaner, and wear down much slower than abrasive discs. You’ll find ferrous-metal-cutting diamond blades for $13 to $40 at bunnings, hardware stores and online.

Cut Metal with Your Circular Saw

It may not be an obvious choice, but fitted with the right blade, a circular saw is a great metal-cutting tool. In our test, it cut through rebar like a hot knife through butter. You can cut mild steel up to about 3/8 in. thick using a ferrous-metal-cutting blade. Be careful, though! Hot metal chips will fly everywhere. Put on your safety gear, keep bystanders away, and cover anything you don’t want to be coated with metal chips. You’ll find ferrous-metal-cutting blades at bunnings, hardware stores and online. There are two types: inexpensive steel-tooth blades and carbide-tooth blades ($8 to $40). Carbide-tooth blades are more expensive but will last longer.

It doesn’t matter if you’re a long-time DIYer or just starting out on some projects, there are some tools of the trade that are crucial in getting jobs done. Here are 23 things every DIYer should own and always have on hand.

What Are The Kinds Of Sheet Metal Materials?

Sheet metal is the basis of all engineering today. We can see it everywhere – from cars and machinery to house facades and furniture.

To utilise sheet metal to its full extent, engineers should first know a thing or two about it. This includes standard measurements, materials, differences in manufacturing and possible forming methods.

Millimetres, Mils & Gauge

Foils, sheets and plates are pretty much the same, with the only difference being in thickness. Thickness is measured in 3 ways – millimetres, mils and gauges. While millimetre is a pretty straightforward unit, mils and gauges are only common in engineering and manufacturing.

One mil equals to a thousandth of an inch. As the British often use mils as a plural for millimetres, it can be a little confusing but the difference is important.

Gauge is another unit for measuring sheet metal thickness. Although official standards discourage the use of gauges, they are not all that rare. Gauge represents the thickness of a metal in relation to its weight per square foot. A higher gauge number means a smaller thickness.

Foil, Sheet and Plate

Having gone over the primary measurement systems, we can now look at the categorisation of foils, sheets and plates. For our purpose, we are going to stick with millimetres as the unit of measurement.

Metal foil is especially common with aluminium, often referred to as tinfoil. The thickness of foil is usually up to 0.2 mm.

Sheet metal is the next in line. The thickness of sheet metal starts from 0.5 mm and goes up to 6 mm. Anything above that is a metal plate.

The thin sheet metal is easy to form, while still providing great strength. At a relatively cheap price, it makes a great fit for most engineering purposes. That is why we see it everywhere around us.

At the end of the article, we will be discussing different forming methods used with sheet metal.

Common Materials

Pretty much all the common engineering metals are also used in the form of sheets. Some of them are carbon steel, stainless steel, copper and aluminium. Choosing the right one for you comes down to the application and requirements of your product.

Metal sheets have the same mechanical properties as the base metal. Thus, steel sheets have high tensile strength and durability suitable for use in constructions and machinery.

At the same time, copper sheets often find use as a decorative layer on modern buildings like Melbourne hotels.

Standard Sizes

Standard measurements apply to both sheet sizes and thicknesses. While achieving large sheet sizes have a few workarounds through welding, you cannot really look past the thickness tables.

Knowing standard sheet sizes helps you with optimising your part layouts. Many times have we received parts for production that are just a bit larger than standard size. That means more scrap and higher overall costs for the customer.

Also, another thing to bear in mind here is the availability of different sheet sizes. While small, medium and large sheets are pretty much always in stock at every sheet metal fabricator’s warehouse, oversized sheets may not be.

Many of them may also not have the machinery to cut such large sheets. So knowing your manufacturers’ capabilities come in handy here.

Sometimes you can just weld together two smaller sheets but it is not the optimal solution. Especially when putting high emphasis on the aesthetics of your project.

What Are The 4 Types Of Manufacturing Processes?

This file type includes high-resolution graphics and schematics when applicable.

It may be surprising to learn that many engineers with great talent and a depth of experience have a hard time answering questions about the type(s) of manufacturing environments that exist in their company.

Most manufacturing environments fit into one of five general categories. Repetitive, Discrete, Job Shop, Process (batch), and Process (continuous).

Most companies use more than one of these environments to get a single product out the door. This is certainly true considering today's use of the supply base versus the historical practices of vertically integrated companies. Vertically integrated companies often had all five environments.

Here’s a closer look at the five environments:

Repetitive: This category, with some exceptions, is best described as having dedicated production lines that turn out the same item, or a closely related family, 24/7 all year long. Speeding up or slowing down the speed of the operation modulates differences in customer demand. There is little setup and changeover activity. If the peak line speed cannot keep up with demand, a second line is added. If demand is not enough for a dedicated second line, it is met by a second line operating in Discrete mode that also makes other products.

Discrete: This environment is highly diverse. It covers a range from few setups and changeovers to frequent setups and changeovers. The products being made may be alike or highly disparate. The more, unlike the products, are, the longer is the unproductive set-up and tear-down time.

Job Shop: Job shops rarely have production lines, they have production areas. The area may assemble only one version of a product, a dozen versions, or even a couple dozen. If demand grows, the operation is turned into a discrete line and selected labour operations are replaced by automated equipment.

These three environments, taken together, are a continuum for mechanical, electromechanical, electronic, and software-driven hardware products. At one end, manufacturing is continuous. At the other end, it is highly intermittent. Designers at the continuous end must be versed not only in the product’s design but also the design of the process equipment. The more repetitive production is, the more likely the environment is dominated by automated equipment. Production personnel rarely touch the product; their role is to oversee the equipment and assure it functions properly.