Angle Grinders mm to inch guide

Ever been asked to grab the 6 inch grinder and had no idea which size to grab? There are many different grinding disc size options to choose from, only an expert metal fabricator would know. We won’t mess around here, lets get into it.

6 inch grinder size in mm

A (six) 6 inch grinder is 150mm

9 inch grinder size in mm

A (nine) 9 inch grinder is 230mm.

9 inch (230 mm) angle grinders have been banned on some work sites due to the increased risk of injury. The increased power and size of the unit will cause more severe kickback and gyroscopic effects (i.e. makes the grinder difficult to use, the power is simply too much for some people to handle)

14 inch grinder size in mm

A (fourteen) 14 inch grinder is 356mm

Common Angle Grinder Sizes in Australia

Grinders also come in various other sizes, such as a 3 inch 76mm angle grinder, however these are the most common sizes used in Australia.

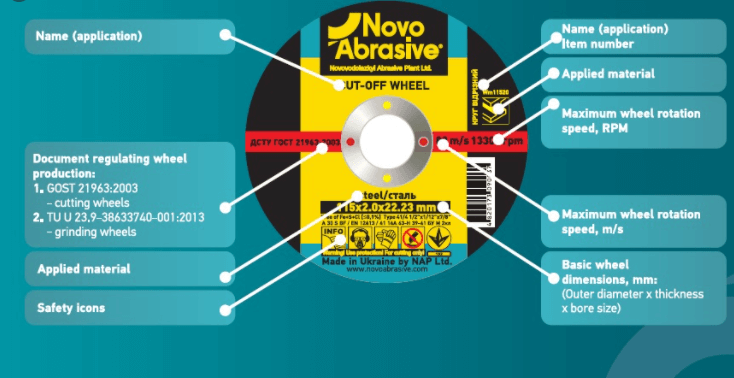

How To Read A Grinding Disc

Different Types Of Grinding Disc

Silicon Carbide Grinding Discs

These discs are purpose made for the shaping of metals. They also allow for the efficient removal of materials and prevention of surface damage. Use of the grinding discs is expected to minimise the need for subsequent processing, allowing preparation time to be saved.

Cutoff Grinding Discs

These discs are purpose made to cut hard items and materials such as rods, bolts, rebars, and metal piping.

Sanding Pads and Discs

Sanding pads allow for the efficient removal of old paint in the process of surface preparation. They are also suitable for coarse and fine sanding.

Grinding Wheels and Discs

The grinding wheel is an expandable wheel, made from an abrasive compound. It allows for a variety of grinding and abrasion functions. Grinding wheels and other forms of bonded abrasives have two key features – the abrasive grains which allow for efficient cutting, and the bond which combines and supports the grains during the cutting process.

Grinding discs are suitable for metal and stone applications across a range of machine sizes. The main use of such discs is in the removal of materials. However, they can also be used for the finishing and preparation of stone and metal surfaces.

Wire Brush Wheels

These wheels allow for the effective removal of paint and rust. They also enable the removal of burrs from rough-cut metal surfaces.

Diamond Cutting Wheels and Discs

These wheels and discs are particularly suitable for the cutting of concrete, tile, masonry, and granite. However, it is important to make the appropriate selection and use of the cutting blade in accordance with the technique. There are diamond blades suitable for dry and wet cutting.

Aluminium Oxide Grinding Wheels

These oxide-based wheels are suitable for a wide range of applications, including woodworking and the cutting of crumbly materials like cutting boards.

Flap Discs and Wheels

The flap disc performs a similar function to the wire brush yet features flaps rather than wires. This allows for the effective combination of weld beads with the rest of the metal.

Pingback: Different Kinds Of Angle Discs – Glasgow Coach Driver

Pingback: Different Kinds Of Angle Discs